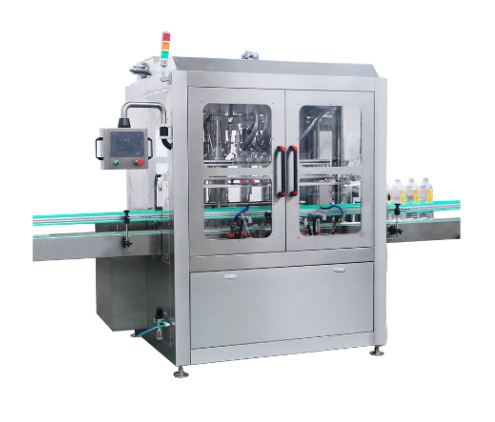

When setting up a detergent filling line, it is important that one choses the right detergent filling machine to assure the productivity and flexibility in the production line. An ideal machine suits both current requirements as well as upcoming expansion and potential changes in products. The following outline shows top attributes to look for in a Detergent Filling Machine to ensure high performance and flexibility through your production.

High-Speed Operation

One of the main characteristics in the design of a filling machine is its speed. Find a machine that fills at least 50 containers per minute. For higher performance, 200 containers per minute or faster, depending on the detergent viscosity and the container size, machine speeds of up to 200 containers per minute and faster are attainable. This scalability enables you to grow with customer and market needs without any bottlenecks.

Precision Filling Technology

The accuracy in filling volumes is essential. In todays era, there are precision metering systems like servo or piston fillers, which can achieve an accuracy as low as 0.5% of the target volume. Such accuracy is essential to ensuring consistent product quality and meeting strict industry standards.

User-Friendly Interface

The training and operation are simplified by the user-friendly interface. Intelligent touch screens give operators the ability to change settings at the touch of a finger to control the entire filling process. This availability minimizes operator error and ensure uninterrupted operation during setups or when addressing issues.

Versatile Container Handling

Being able to handle multiple container sizes and types. It should be able to fill from 100 ml to filing up to 5 liters for which a good sturdier machine must be available. Fast-change parts and adjustable guides help changeover container formats, greatly improving line efficiencies and (limited) flexibility.

Robust Construction

The material of construction of your machine will determine how long it lasts and also if it is able to work with harsh chemicals. As you would expect, the stainless steel is noted for its durability and corrosion resistance. If you opt for those cleaning solutions, ensure that any machine components that come into contact with detergent are constructed out of type 316L stainless steel, which provides superior defense against harsh chemicals.

Compatibility with Integrated Systems

In addition, other elements of the production line, such as capping machines and labeling stations, can be integrated into a machine, creating more efficient combination systems. Streamlines Process Flow - The movement of the machine from upstream to downstream equipment must minimize the transition time and process downtime to run more products per day through this single machine.

Safety Features

In chemical filling operations, safety is key. Find devices that are sealed to avoid spilling and splashing, to protect the operator and to minimize waste. Emergency stops and safety interlocks are important features that keep the work environment safe.

Support and Warranty

Easily accessible customer support and a sturdy warranty are testaments to a manufacturer's faith in the product they deliver. Choose equipment with full-service support, from installation and training to service. First off, a warranty of one year or longer is a peace of mind to protect you against early defects.

Choose a detergent filling machine with these features in mind, and you will get something that fits your needs now but can grow with your business too. The takeaway: When it comes to technology, an investment in the right tools and systems is sure to translate into efficiency, better value, and high-quality results.